If someone forwarded you this briefing, sign up here to get the Index Insider every Friday.

WORK SMARTER, NOT HARDER

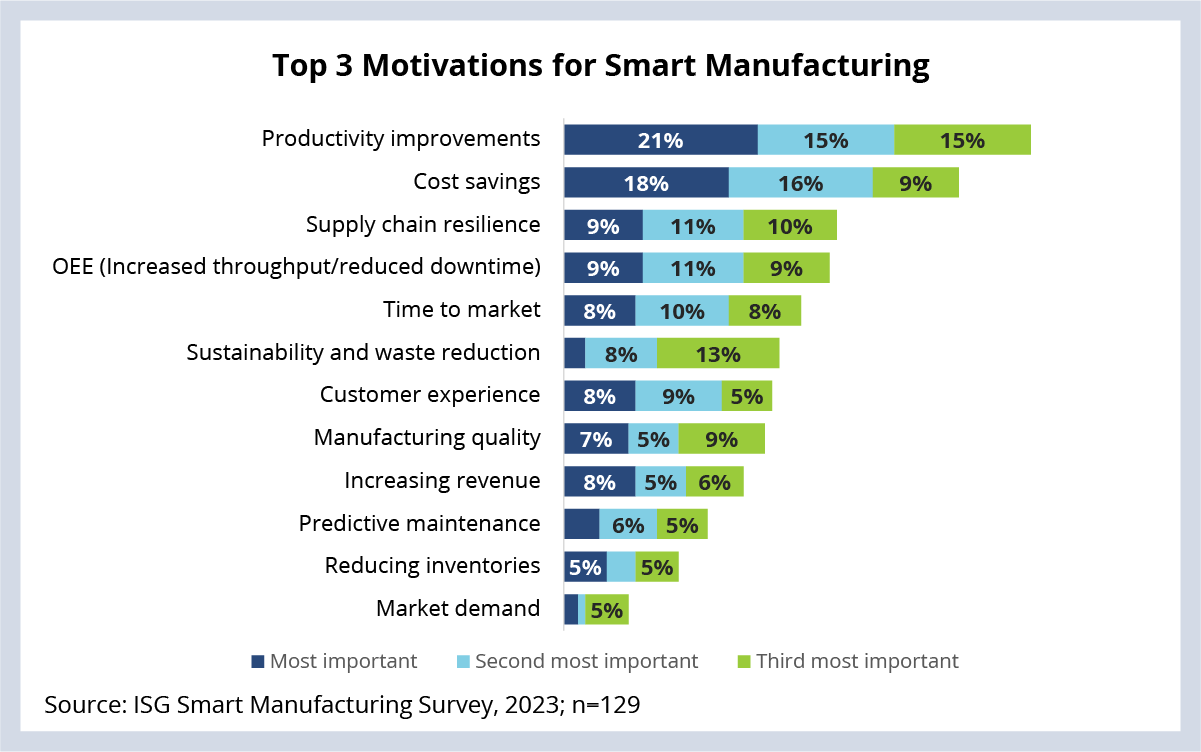

When ISG first studied the adoption of smart manufacturing a year ago, we found enterprises were most interested in using the technology to reduce cost and waste. This was when organizations were reacting to the rapid inflation of material-input prices and the pervasive supply shocks of 2021-22. This year, cost savings and supply chain resilience remained priorities but no longer topped the list. The data show that productivity (in a manufacturer’s plant, processes and people) is now the highest-rated motivation, with overall equipment effectiveness also moving up the chart.

This draws some parallels to our recent cost optimization study, which highlights that, despite an overall focus on cost optimization and savings across industries, specific transformation programs are still on the critical path for many businesses. The data suggest smart manufacturing is no different.

Our study shows that most manufacturers have built their smart manufacturing programs to be explicitly cross functional and, despite relying on technology, rarely report into the IT departments. For manufacturers, these initiatives are business-critical and the data below show the same story. (See Data Watch). This is not about scaling back costs as much as working smarter and making more products with what you already have.

If this topic is interesting to you, please join us at ISG TechXchange: Smart Manufacturing next month, May 22-23 in Chicago. And if you are interested in seeing more data from this study, please let us know.

DATA WATCH